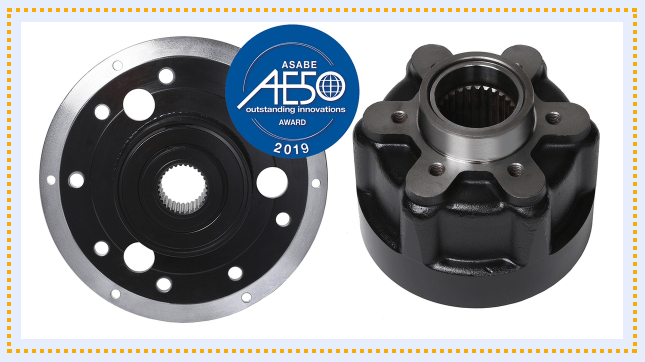

The American Society of Agricultural and Biological Engineers (ASABE) has named Weasler Engineering’s High-Torque Automatic Clutch the winner of a 2019 AE50 award. AE50 awards honor the year’s most innovative designs in engineering products or systems for the food and agriculture industries.

“We’re pleased and honored to earn this prestigious distinction from ASABE,” noted Tyler Johnson, Weasler design engineer. “Our new high-torque automatic clutch helps farmers improve safety, enhance productivity, and increase profits.”

Johnson explained that the new component is specifically designed for high-torque and high inertia applications, such as large square balers, combines, and self-propelled forage harvesters. “When torque overload occurs, the clutch automatically disengages to protect costly equipment from power spikes,” he said. “But, it then automatically reengages when power is reduced to a safe level, so there is no need for the farmer to stop and reset the clutch or replace a bolt.”

For agricultural OEMs, Weasler’s new clutch offers optimal design flexibility. “Our through shaft design enables a range of mounting options, from flywheels and sprockets to flanges or hubs,” Johnson added.

Our High-Torque Automatic Clutch Performance Benefits

- Repeatable high-torque overload prevention protects equipment, minimizing downtime and maximizing harvest rates.

- Minimal torque spikes during clutch disengagement reduce damaging energy from reaching costly sub-systems that are critical to your equipment.

- Low rpm re-engagement for high-inertia applications minimizes the amount of heat generated during an extended slip as the implement comes to a full stop.

- Minimal heat generation extends clutch life, eliminating the need to re-lubricate.

- Maintenance-free, sealed clutch requires no additional lubrication, saving you time and money.

- Audible alert indicates when the clutch disengages and re-engages, so operator knows to reduce power due to torque overload.

- Rpm sensor compatibility allows for easy integration of computer monitoring system.

Our High-Torque Automatic Clutch Design Features

- Performance: Weasler Engineering’s patented clutch design minimizes torque spikes during disconnect, which results in increased downstream component life and makes the clutch ideal for high inertia applications.

- Design: Adaptive design allows mounting flexibility to meet a wide array of your needs, including flange bolt patterns, flywheels, sprockets, and hubs. Driver bores are available up to 65 mm. Through-shaft design increases mounting flexibility and applications. Wear resistant materials ensure repeatable protection and durability. Sealed design requires zero maintenance for the life of the clutch.

- Torque settings available up to 6000 Nm.

- Wide range of operating speeds are available upon request.

- 100% shop tested and serialized.

download a brochure on our new award-winning clutch!

About ASABE and AE50 Awards

ASABE is an international scientific and educational organization dedicated to the advancement of engineering applicable to agricultural, food, and biological systems. The AE50 awards program emphasizes the role of new products and systems in bringing advanced technology to the marketplace. These engineering developments help farmers, food processors and equipment manufacturers increase efficiency, enhance quality, improve safety, and increase profits. Companies from around the world submit entries to the annual AE50 competition and up to 50 of the best products are chosen by a panel of international engineering experts.

What can we design for you?

Let Weasler engineers help you match a system for your specific application. We can design a clutch solution to meet your exact torque capacity or RPMs, and one that mounts or connects as needed. Email oemsales@weasler.com now.