Below you will find some of Weasler’s most frequently asked questions about our PTO Drive Shafts and Clutches & Dampers.

If you can’t find what you are looking for, please contact us.

Power Take Off (PTO) Drive Shafts

1. What is a Power Take-Off (PTO) drive shaft and what does it do?

A PTO drive shaft is a crucial component in farming machinery. It transfers power from a tractor to various implements, such as balers, mowers, and grain mixers.

Here’s a breakdown of its functions:

-

- Power Transmission: It connects the tractor’s PTO to the implement, allowing the tractor’s engine to power the implement.

- Versatility: Used in a wide range of equipment, including hay balers, rotary mowers, and irrigation systems.

- Durability: Designed to withstand the rigorous demands of agricultural work, ensuring reliable performance.

2. How do I identify and measure a PTO drive shaft?

Identifying and measuring a PTO drive shaft involves a few key steps. Here’s a simple guide to help you:

Identifying the PTO Drive Shaft

- Check the Type: PTO shafts come in different types, such as North American spline shafts and German and Italian profile tubes. Each type has various series options based on bearing diameter, cap-to-cap overall length, and snap rings.

- Parts Identification: Familiarize yourself with the parts of the PTO shaft, including the internal and external yoke (connection to the tractor), universal joint, and guarding (safety chain and safety shield).

The Weasler website also has an interactive series finder to help identify your PTO drive shaft.

Measuring the PTO Drive Shaft

Measure the Shaft Length:

-

- Ensure the shaft is in the closed position (smallest length).

- Use a measuring tape to measure from the outside of each yoke. This is the closed length.

Measure the Universal Joint:

-

- Measure the length from one outer end to the other.

- Record the width of one end of the universal joint.

Combine Measurements:

-

- Use both measurements to find the correct PTO series size for your tractor’s horsepower.

- You can refer to a PTO yoke size chart or use a PTO Series Discovery Tool for accurate sizing.

Additional Tips

-

- Safety First: Always ensure the safety guard is in place and in working order.

- Know Your Implement Connection: Determine if you have a shear pin, clutch, or splined implement end.

3. What’s the difference between North American and metric PTO drive shafts?

The primary differences between North American (domestic) and metric PTO (Power Take-Off) drive shafts lie in their shapes and design characteristics:

North American (Domestic) PTO Drive Shafts

-

- Shapes: Typically square, rectangular, hexagonal, or splined.

- Design Focus: These shapes are designed for robustness and durability, making them suitable for heavy-duty agricultural applications where ease of replacement and maintenance are important.

- Applications: Commonly used in North American farming equipment, where high torque loads are frequent.

Metric PTO Drive Shafts

-

- Shapes: Often feature bell, lemon, or star shapes.

- Design Focus: These designs are engineered for constant velocity and reduced friction, which is beneficial in applications requiring smoother transitions under variable loads.

- Applications: More common in European machinery, where smoother telescoping movements and reduced friction are prioritized.

Both types serve the same fundamental purpose of transferring power from the tractor to the implement, but their design differences cater to the specific needs and conditions of their respective regions.

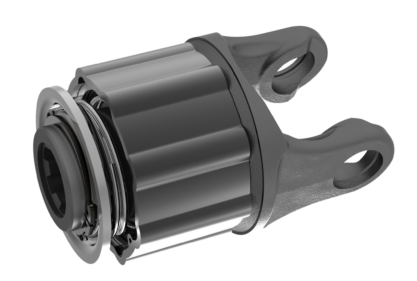

4. What are the main components of a PTO drive shaft and can I replace them individually?

The main components of a PTO drive shaft include:

-

- Drive Shaft: This is the central component that transmits power from the tractor to the implement.

- Universal Joint: These joints allow the drive shaft to flex and accommodate movement between the tractor and the implement.

- Yoke: The yoke connects the drive shaft to the tractor and the implement.

- Safety Guard: This is an important safety feature that covers the rotating parts to prevent accidents.

Each of these components plays a crucial role in ensuring the efficient and safe transfer of power.

5. How do I maintain a PTO drive shaft and how often should I grease it?

Maintaining a PTO (Power Take-Off) drive shaft involves several key steps to ensure its longevity and optimal performance. Here’s a general guide:

Maintenance Steps

-

- Disassemble the PTO Shaft: Slide the shaft apart and remove any protective covers.

- Clean the Shaft: Wipe off any excess grease, dirt, or debris.

- Apply Fresh Grease: Use a grease gun to apply grease evenly over the shaft telescoping members, universal joints and PTO safety shield raceway bearings.

- Reassemble the Shaft: Align the parts correctly and reassemble the shaft.

- Lubricate Moving Parts: Oil the lock pin and grease the inside of the coupling to prevent corrosion.

Greasing Frequency

-

- Regular Use: Grease “R-Kits” every 8 hours of operation, “E-Kits” every 50hrs of operation.

- Infrequent Use: Grease before each use or at least annually.

6. What causes vibration in a PTO drive shaft and how can I prevent it?

Vibration in a PTO drive shaft can be caused by several factors:

-

- Misalignment: Incorrect alignment of the drive shaft can lead to vibrations. This includes improper angles between the drive shaft and the equipment it connects to.

- Worn or Damaged U-Joints: Universal joints (U-joints) that are worn out or damaged can cause vibrations. These joints need to be in good condition to function smoothly.

- Loose Components: Any loose parts or components in the drive shaft assembly can contribute to vibrations.

- Bent Shaft: A bent or damaged shaft can cause significant vibrations.

To prevent and fix these vibrations, you can:

-

- Check Alignment: Verify that the drive shaft is correctly aligned with the equipment. Adjust the angles if necessary to ensure proper alignment.

- Inspect and Replace U-Joints: Regularly inspect the U-joints for wear and damage. Replace them if needed.

- Tighten Loose Components: Check for any loose parts in the drive shaft assembly and tighten them.

- Replace Bent Shaft: If the shaft is bent, it should be replaced to eliminate vibrations.

Regular maintenance and inspections can help identify and prevent these issues and ensure smooth operation of your PTO drive shaft.

7. Are Weasler shafts compatible with all tractors and implements?

Weasler shafts are designed to be highly versatile and compatible with a wide range of tractors and implements. They offer different types of drive shafts to meet various needs:

-

- Standard Drive Shafts: Suitable for applications like rotary cutters, tillers, and fertilizer spreaders. These are designed for occasional duty cycles and can handle up to 80 horsepower.

- Classic Drive Shafts: Ideal for rotary cutters, combine headers, balers, mower conditioners, mixer feeders, and manure spreaders. These can handle up to 170 horsepower for intermittent duty cycles.

- Professional Drive Shafts: Built for continuous duty cycles, suitable for combines, forage harvesters, balers, and other heavy-duty equipment. These can also handle up to 170 horsepower.

Weasler shafts come with various yoke options and telescoping profiles to ensure compatibility with different equipment. However, it’s always a good idea to check the specific requirements of your tractor and implement to ensure the best fit.

8. What safety features are included and how do they work?

PTO drive shafts are equipped with several safety features to prevent accidents and injuries. Here are some key safety features and how they work:

-

- PTO Guard: This is a protective cover that surrounds the PTO shaft. It prevents accidental contact with the rotating shaft, reducing the risk of entanglement with clothing, jewelry, or hair.

- Shear Pin: This device is designed to break if the PTO shaft becomes jammed or overloaded. By breaking, it prevents damage to the driveline and reduces the risk of injury.

- Slip Clutch: This mechanism allows the PTO shaft to slip if there is a sudden increase in load, preventing damage to the equipment and reducing the risk of injury.

- Overrunning Clutch: This feature allows the implement to continue rotating after the tractor PTO is disengaged, preventing the implement from driving the tractor.

- Telescoping Shaft: This allows the PTO shaft to adjust its length to accommodate different equipment setups, ensuring proper alignment and reducing stress on the driveline.

- Universal Joints: These joints allow the PTO shaft to flex and bend, accommodating different angles between the tractor and implement. Proper maintenance and inspection of these joints are crucial for safe operation.

Regular inspection and maintenance of these safety features are essential to ensure their effectiveness. Always follow the manufacturer’s guidelines and safety recommendations when using PTO drive shafts.

9. What if a drive shaft is too long for my needs?

Weasler offers a range of cut-to-length drive shafts, particularly for PTO applications. These drive shafts are designed for heavy-duty use in agriculture and other industries. Here are some key features:

-

- Design Adjustability: The drive shafts can be cut to the desired length to fit specific applications. Here is a video to help guide you.

- Interchangeability: They are compatible with most competitor models. Here is a make/model finder to show compatibility.

- Profiles Available: Tri-lobe, lemon, and star shaft profiles.

- Easy Lock Guard Construction: This allows for quick and easy assembly or removal with simple tools.

10. Where can I find manuals, warranty info, or support?

Our website has a resources section with access to product guides, instructional manuals, service and maintenance instructions, and more. If you cannot find what you’re looking for you can reach out to our technical support team as well.

11. How do I safely remove or install a PTO drive shaft?

Removing or installing a PTO (Power Take-Off) drive shaft can be a bit tricky, but with the right steps and precautions, you can do it safely. Here’s a general guide:

Removing a PTO Drive Shaft

-

- Turn Off the Engine: Ensure the tractor or vehicle is turned off and the parking brake is engaged.

- Disconnect the Implement: If the PTO shaft is connected to an implement, disconnect it.

- Locate the PTO Output Shaft: Find the PTO shaft at the rear of the tractor.

- Release the Locking Mechanism: Depending on your PTO shaft, you might need to press a push pin, pull a collar, or remove a bolt to release the shaft.

- Lubricate if Stuck: If the shaft is stuck, apply a penetrating lubricant and gently tap it with a hammer to loosen it.

- Pull the Shaft Out: Once the locking mechanism is released, pull the shaft out carefully.

Installing a PTO Drive Shaft

-

- Inspect the Shaft: Check the PTO shaft for any damage or wear. Ensure it is properly lubricated.

- Align the Shaft: Align the PTO tractor yoke spline with the tractor’s PTO output shaft spline.

- Engage the Locking Mechanism: Slide the shaft onto the PTO output and engage the locking mechanism (push pin, collar, or bolt).

- Connect the Implement: Attach the implement to the other end of the PTO shaft.

- Check for Proper Operation: Start the tractor and engage the PTO to ensure everything is working smoothly.

Safety Tips

-

-

- Wear Protective Gear: Always wear gloves and safety glasses.

- Avoid Loose Clothing: Loose clothing can get caught in moving parts.

- Use Proper Tools: Ensure you have the right tools for the job.

- Follow Manufacturer’s Instructions: Always refer to the manufacturer’s manual for specific instructions related to your equipment.

-

12. What is the maximum operating angle for a Weasler PTO drive shaft?

Weasler features up to 80 degrees of movement with our CV design. We can also engineer a variety of options to help our customers achieve their application needs. Contact us for more information.

13. How do I store a PTO drive shaft when not in use?

Storing a PTO drive shaft properly when not in use is crucial to maintain its performance and longevity. Before storing, clean the drive shaft thoroughly with a penetrating oil and a wire brush to remove any debris or rust. Inspect it for any signs of wear, cracks, or other damage. If any damage is found, repair or replace the shaft before storage.

Clutches & Dampers

1. What is a torque limiter, and how does it protect equipment?

A torque limiter, or clutch, is a mechanical device designed to protect equipment from damage caused by excessive torque, which can occur during mechanical overloads. It instantly disengages the drive when excessive torque is detected, safeguarding equipment from potentially damaging overloads that can cause costly repairs and downtime.

Here is more information on how it works and how it protects equipment:

How a Torque Limiter Works

-

- Normal operation: During normal operation within the equipment’s safe operating limits, the torque limiter transmits torque from the driving shaft to the driven components, such as gearboxes, secondary shafts, pulleys or sprockets, ensuring smooth power transfer while protecting the system from overload.

- Torque overload: When the transmitted torque exceeds a preset limit, the clutch mechanism within the torque limiter can no longer maintain engagement. At this point, the torque limiter slips, effectively interrupting the torque transmission and disconnecting the driven components from the driving shaft. This slip action protects downstream equipment from potential damage due to overload.

- Resetting the torque limiter: Once the overload condition is removed, most Weasler torque limiters will re-engage automatically. However, shear bolt torque limiters do not automatically reset and require replacement of the shear bolt(s) before restarting the machine. Always refer to your machine operator’s manual for proper shear bolt selection and installation procedures.

Protection Mechanism

-

- Acts as a mechanical circuit breaker: Similar to an electrical circuit breaker, a torque limiter automatically disconnects the mechanical drive during a high torque event to protect the system from damage.

- Prevents damage: By slipping during torque overloads, torque limiters prevent excessive torque from reaching and damaging critical components such as couplings, drive shafts and gearboxes.

- Reduces downtime: This protection helps avoid mechanical failures, reducing downtime and costly machine repairs.

Benefits

-

- Equipment longevity: By preventing mechanical overloads, torque limiters play a crucial role in extending machinery lifespan and ensuring long-term operational reliability.

- Operational efficiency: Torque limiters ensure your equipment operates within safe torque limits, helping prevent costly downtime and allowing you to maximize the efficiency and reliability of your operations. Torque limiters are vital across industries such as manufacturing, mining and agricultural equipment, where they protect high-powered machinery from the damaging effects of mechanical overloads.

2. How do I choose the right clutch?

Choosing and installing the right clutch involves several key considerations and steps. Here’s a guide to help you through the process:

-

- Determine your application needs:

-

- Torque range

- Application disconnect frequency and duration

- Transmitted torque during disconnect

- Re-engagement method

- Cost of ownership

-

- Compare application requirements to the clutch performance characteristics shown in table below to determine which solution best fits your application needs:

Ball Shear

Friction Clutch

Ratchet Clutch

Auto ClutchRelative Cost $ $$ $$ $$$ Torque Range 3,000 - 50,000 in-lbs.

340 - 5,650 Nm6,000 - 24,000 in-lbs.

680 - 2,700 Nm1,000 - 13,250 in-lbs.

120 - 1,500 Nm1,400 - 53,000 in-lbs.

160 - 6,000 NmCost of Ownership Low Medium Medium Low Re-engagement Method Manual bolt replacement Automatic when torque drops below 50% Automatic when torque is reduced Automatic when speed and torque are reduced Transmitted Torque During Disconnect None Constant ~60% Pulsing ~0-110% Pulsing ~0-20% Regular Maintenance None Seasonal check/adjustemnts, replace friction disc as needed Grease every 50 hours, or upon disconnect None Typical Applications Snowblowers, Grain Augers, Manure Spreaders, Mixer Feeders, Bale Processors Mower Conditioners, Rotary Cutters, Balers, Tillers, Shredders Combine Headers, Combine Drives, Rakes and Tedders Balers, Combine Headers, Combine Drives, Grain Carts, Manure Spreaders, Mixer Feeders Application Disconnect Duration Up to 5 minutes <10 seconds <30 seconds Up to 5 minutes Application Disconnect Frequence Very Infrequent Frequent Frequent Very Frequent - Review the resources available on our Clutches Product Page for more product information.

- Determine your application needs:

3. What types of clutches does Weasler offer and how do they differ?

Weasler offers several types of clutches for various application and torque ranges. Our website outlines and compares product specifications for each type:

- Overrunning – Prevents torque transmission in the non-driving direction

- Ball shear – Shear bolt device that generates no pulsing torques during disconnect

- Friction clutch – Continues to transmit torque at a reduced level during overload and automatically re-engages when overload is removed

- Ratchet – Automatic re-engaging torque limiter with high pulsing torques during disconnect that aid in pushing through obstructions

- Automatic – Maintenance-free, automatic, re-engaging torque limiter with reduced pulsing torques during disconnect for reduced heat generation and improved durability

4. Can I adjust the torque setting on a clutch?

While most of Weasler’s clutches are not adjustable, our open-coil, spring, friction clutches can be adjusted. Refer to your operator’s manual for proper torque setting. If you need assistance with adjustment procedures, please contact us.

5. What are the signs of clutch wear and how often should I inspect it?

Signs of torque limiter wear:

-

-

- Abnormal sounds – Unusual noises during operation, especially at start up or during and overload event, can indicate wear or improper installation.

- Frequent slippage or nuisance disconnects – If the torque limiter slips more frequently than usual or under lower load conditions, it may be worn out and unable to handle the set torque threshold. Friction clutches can be readjusted by following our service and maintenance instructions.

- Visible damage – Excessive wear or damage indicates the need for replacement. Visually inspect for the following:

- Signs of wear on the friction surfaces, springs, o-rings, seals and other components

- Physical damage such as cracks, dents or missing components

- Signs of overheating such as burnt or dried lubricant or discolored components

-

Inspection frequency

Regular inspections and maintenance of your torque limiter can help prevent unexpected failures and extend the lifespan of your equipment. Refer to your owner’s manual for the required maintenance intervals and procedures. If not specified in your owner’s manual, inspect the torque limiter during other routine maintenance checks or at least quarterly, depending on the usage and operating conditions.

Always perform an inspection after any significant overload event, such as long disconnect times or numerous disconnects over a short period of time, to ensure the torque limiter is still functioning correctly. For ball shear and ratchet clutches, significant or long disconnect times require regreasing.

6. What is a damper, and what are its benefits?

Weasler torsional dampers are engineered to provide significant vibration reduction in powertrain systems and protect drivetrain components from excessive wear. By reducing torsional vibration, our dampers provide greater comfort for operators and reduce wear on equipment for longer life.

Weasler offers two types of torsional dampers:

-

- Shock absorbing couplers

- Flywheel damper

Visit our Dampers Product Page to learn more.

7. Are Weasler clutches compatible with other brands?

Compatibility depends on several factors, such as:

-

- Connecting shaft size and spline configuration

- Locking mechanism (Spring-Lok, Safety Slide Lock)

- Driveline series and style (e.g., spline, square, lemon, star or triangular)

- Torque rating and range

View our available aftermarket clutches here. To ensure compatibility, it’s best to compare technical specifications directly or consult with a local dealer or distributor. You can also contact our technical support team.

8. Can I retrofit a clutch or damper to an existing shaft?

Adding a torque limiter to an existing shaft may be possible but depends on many factors:

-

- The length of the drive shaft must be adjustable to accommodate the difference in length of the torque limiter and the yoke it is replacing, without impacting the required telescoping length for the application.

- The appropriate torque setting will need to be determined based on the equipment manufacturers’ recommendations.

Placement and guarding of the added torque limiter needs to meet all necessary safety standards. Refer to the Agricultural Driveline Manufacturers Association Safety Resources website for all applicable standards such as ISO 4254-1 2015, ANSI/ASABE S318.18 (2017) and ANSI/ASABE S604.3 (2020).

Adding a torque limiter requires careful consideration. We recommend you consult with a local dealer or distributor, or contact our technical support team to determine feasibility.

9. Do Weasler clutches need lubrication?

The need for routine lubrication depends on the type of clutch. For those clutches that require periodic lubrication, be sure to grease the device before putting it into operation, after any prolonged period of not using the equipment, or after a significant overload event, such as long disconnect times or numerous disconnects over a short period of time.

For routine lubrication requirements, refer to your owner’s manual. If requirements are not provided, use our recommended lube intervals shown below:

-

- Overrunning – Lubricate the clutch every 250 shaft operating hours (14g)

- Ball shear – Lubricate the clutch every 250 shaft operating hours (14g)

- Friction clutches with overrunning – Lubricate the overrunning device every 250 shaft operating hours (14g)

- Ratchet – Lubricate the clutch every 50 shaft operating hours (25g)

- Automatic – Maintenance-free

Instruction manuals are available on our website for the following drive shafts:

For more information, contact our technical support team.

10. What causes clutch slippage?

Torque limiter slippage can be caused by several factors, depending on the type of torque limiter, including friction, shear bolt or ratchet. Here are the most common causes:

Overload conditions

-

- Cause: The applied torque exceeds the preset torque limit.

- Effect: The torque limiter slips to protect the driveline from damage.

- Solution: This is normal behavior. If it happens frequently, adjust operating parameters to stay within safe operating limits.

Friction clutch – worn or contaminated friction discs

-

- Cause: Friction discs degrade over time or become contaminated with oil, grease or dirt.

- Effect: Reduced friction leads to premature or continuous slippage.

- Solution: Clean or replace the friction discs.

Incorrect torque setting

-

- Cause: The limiter is set too low for the application.

- Effect: It slips under normal operating loads.

- Solution: Adjust the torque setting to match the equipment’s requirements. Refer to your owner’s manual for safe operating limits.

Friction clutch – spring fatigue or failure

-

- Cause: Springs break or lose tension over time.

- Effect: Inadequate pressure on friction discs causes slippage.

- Solution: Replace the springs or the entire clutch assembly if needed.

Misalignment or Installation Issues

-

- Cause: Improper installation or shaft misalignment.

- Effect: Abnormal loads or vibration can lead to nuisance disconnects.

- Solution: Reinstall the clutch properly and ensure alignment.

Damage to clutch

-

- Cause: Damage from misuse or mishandling.

- Effect: Damage to clutch mechanism prevents it from acting appropriately.

- Solution: Replace clutch.

11. Where can I get support, parts or warranty info?

Consult with a local dealer or search the Find a Distributor section of our website. If you are not able to obtain helpful information, contact our technical support team.

12. Are there maintenance-free clutch options available?

Weasler automatic clutches are maintenance-free and sealed, meaning they do not require additional lubrication. This design helps reduce downtime and maintenance costs while improving reliability in high-inertia applications like balers and forage harvesters.

Find a Distributor

Product Finder

MARKETS WE SERVE

PRODUCT FINDER

![]()

Weasler is part of CentroMotion, a global manufacturing company specializing in friction products, information and control devices, mechanical power transmission products, and thermal and motion controls.

CentroMotion Brands: Carlisle Brake & Friction | CrossControl | Elliott Manufacturing | Gits Mfg. | maximatecc | Power-Packer | Power-Packer North America | Weasler