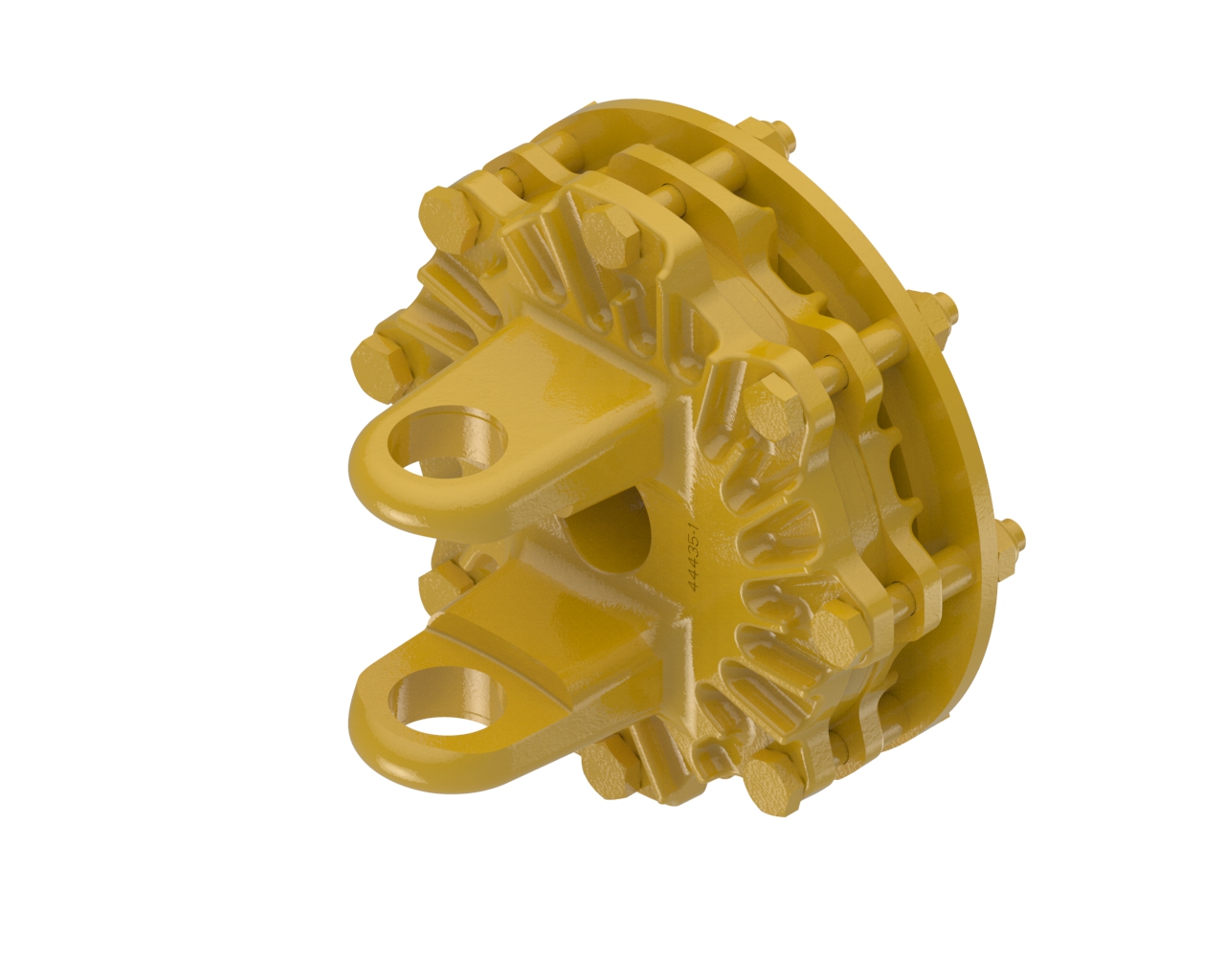

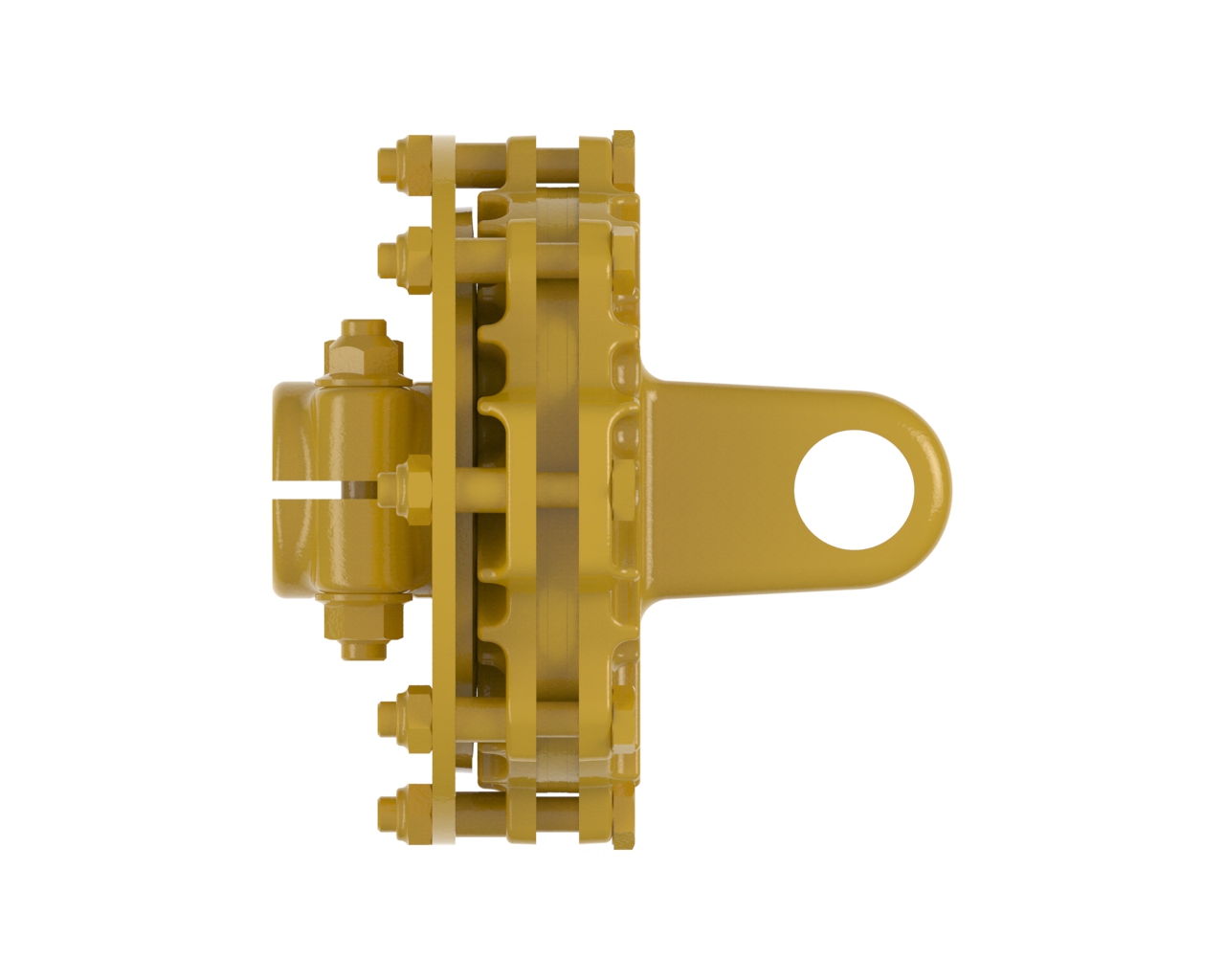

Integral Friction Clutch

Integral Friction Clutch

The INTEGRAL friction clutch is indispensable in certain agricultural implement applications. The friction clutch is the only torque limiter that has the ability to continuously transmit power (at a reduced level) while overloaded. This is valuable during start up of high inertia machines, as well as for leveling out torsional fluctuations due to high cyclic loads. The TorQmaster patented technology dissipates heat quickly, improving durability while protecting the machine.

PERFORMANCE BENEFITS

IMPLEMENT OVERLOAD PROTECTION.

ISOLATES AND DISSIPATES HEAT MINIMIZING DOWNTIME FOR HIGHER PRODUCTIVITY.

CORROSION RESISTANT FRICTION DISCS.

OPTIMIZED DESIGN AFFORDS MORE RELIABLE TORQUE SETTING.

MINIMAL MAINTENANCE.

EASILY ADJUSTABLE TO OPTIMIZE THE CAPACITY OF THE IMPLEMENT.

SMOOTH OPERATION, NO DAMAGING TORQUE SPIKES.

TORQUE TRANSMISSION WHILE SLIPPING AIDS IN DISLODGING PLUGS FOR INCREASED PRODUCTIVITY.

DESIGN FEATURES

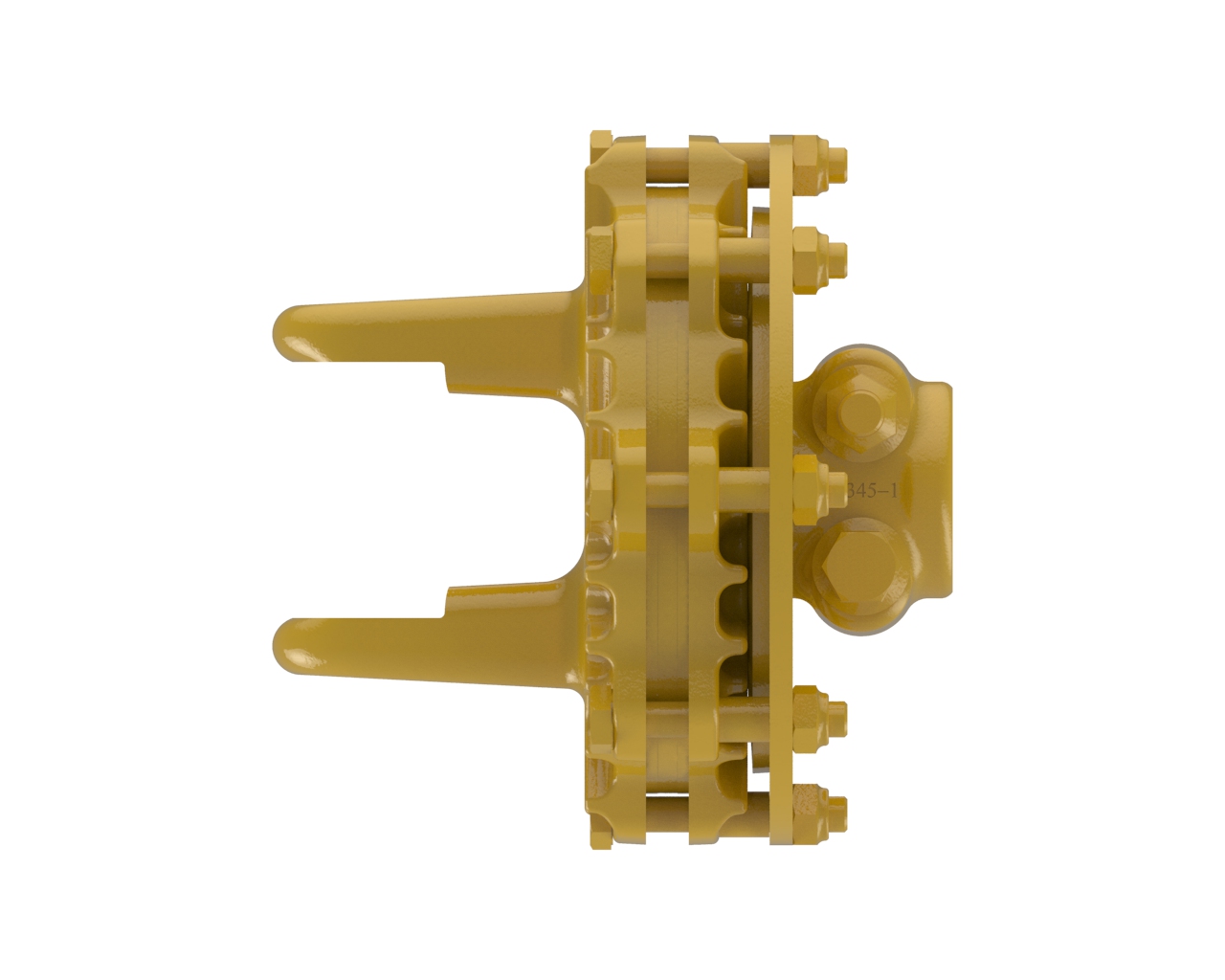

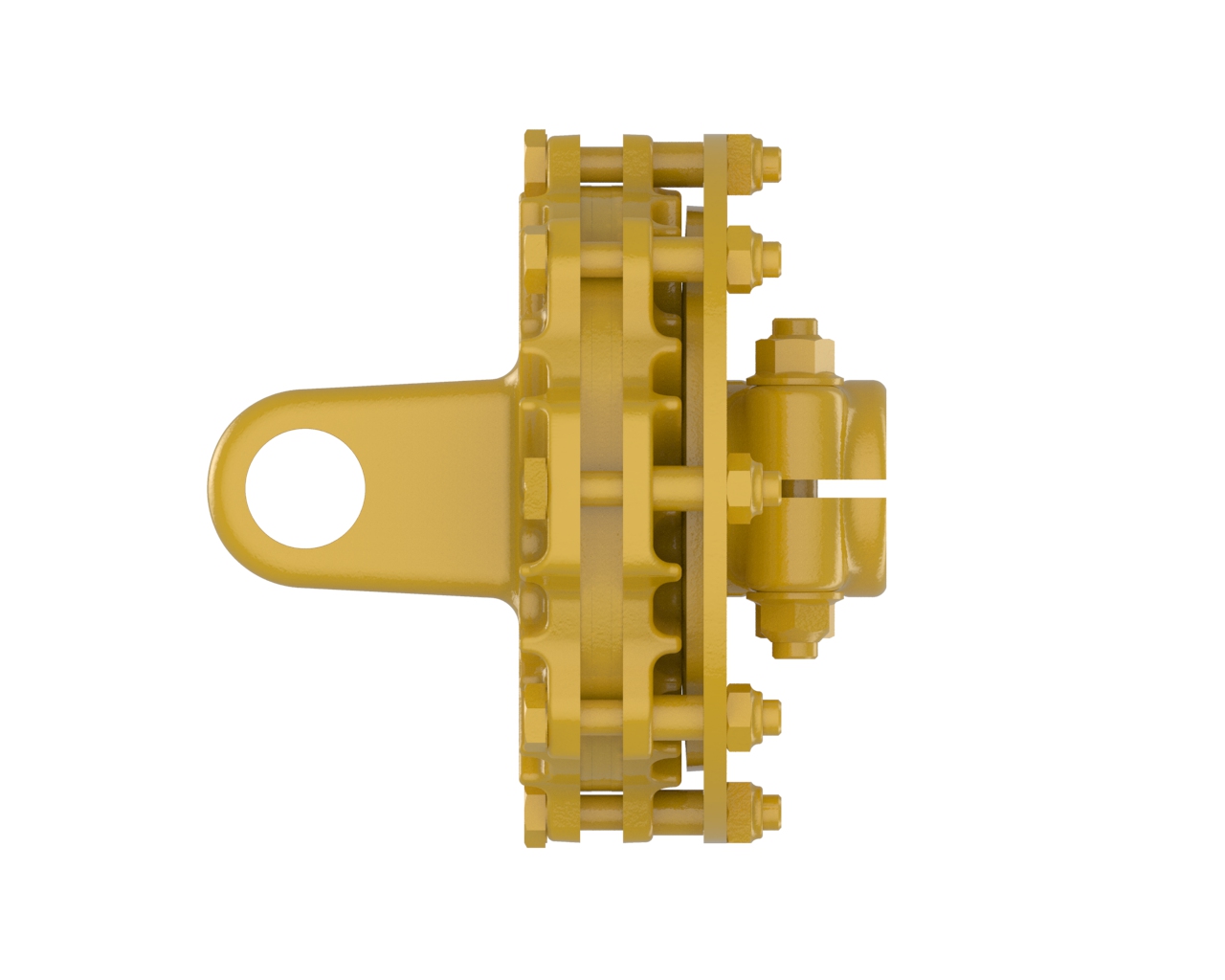

OFFERED IN VARIOUS DRIVE SHAFT SERIES AND HUB CONFIGURATIONS

– YOKE OPTIONS INCLUDE MOST NORTH AMERICAN AND EUROPEAN SERIES

– TAILORED FOR GEARBOX SHAFTS WITH LARGE SPLINES

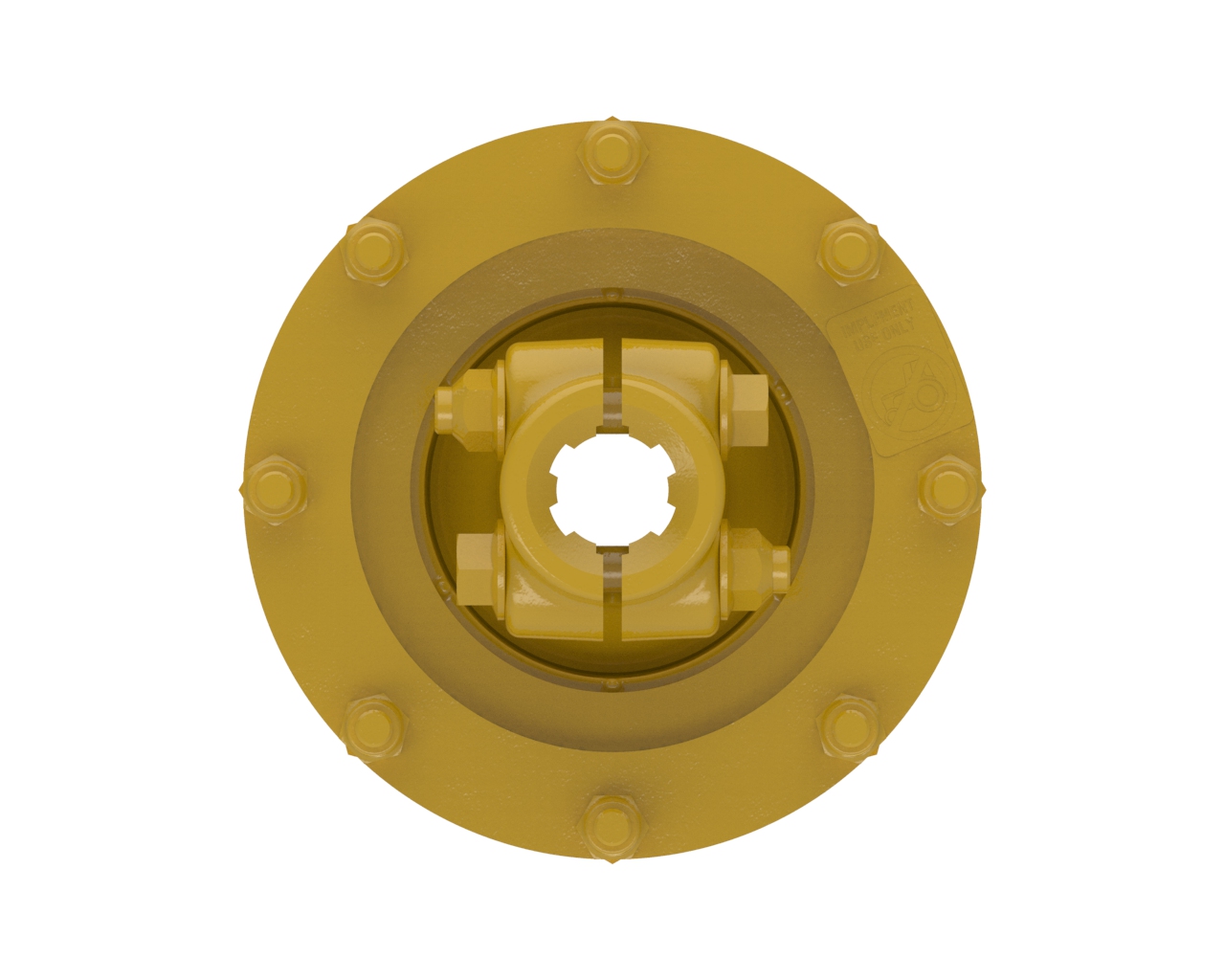

INTEGRAL FLANGE YOKE

– INCORPORATED FINS QUICKLY DISSIPATE HEAT

INTEGRAL SEPARATOR PLATE

– SLIP SURFACES ARE CONTROLLED TO BE AGAINST IRON FOR EFFICIENT HEAT DISSIPATION THEREFORE MORE

RELIABLE FRICTION COEFFICIENT THAN A FOUR DISC CLUTCH (PATENTED)

GRAY IRON PRESSURE PLATE

– FINS ARE INCORPORATED TO QUICKLY DISSIPATE HEAT AND ISOLATE IT FROM OTHER COMPONENTS

– MAINTAINS FLATNESS BETTER AT HIGHER TEMPERATURES ALLOWING MORE EFFICIENT USE OF FRICTION DISCS

SPRING OPTIONS

– OPTIONAL DISC SPRING ALLOWS THE FRICTION DISCS TO WEAR UNIFORMLY FOR EXTENDED LIFE

– OPTIONAL COIL SPRINGS ALLOW ADJUSTABILITY

– TORQUE PROTECTION LEVEL IS DETERMINED BY SPRING SELECTION AND VERIFIED FOR EACH ASSEMBLY

– MADE OF HEAT RESISTANT MATERIAL

TORQUE SETTINGS AVAILABLE FROM 9000 TO 24000 inlb (1000 TO 2700 Nm)

Specifications

| Spec. | Imperial | Metric |

|---|

Downloads

| Document Name | Type | Language |

|---|---|---|

| Service Instructions - Lubricating PTO Drive Shaft.pdf | Maintenance Document | English |

| Service Instructions - Universal Joint.pdf | Service Document | English |

| Lack of Grease - Cross & Brg Kit.pdf | Troubleshooting Document | English |